Beamfox Proximity v1.7.0 available now

We are thrilled to kick off the new year with an exciting announcement: the release of feature update 1.7.0 of Beamfox Proximity! The new release is one of the largest-ever updates to the software, and brings several highly-requested features and under-the-hood improvements. New users can download a 30-day, fully featured, free trial of the software, and existing users with version upgrade licenses can update to the newly released version. Visit the Downloads page to download the new version, or keep reading to learn all about what is new in Beamfox Proximity.

Advanced write field placement and control

In what constitutes one of the largest-ever improvements to the software, we have now added the option to handle write fields directly in the user interface of Beamfox Proximity.

Being able to place and manage write fields directly within Beamfox Proximity greatly simplifies and streamlines the data preparation process, allowing users to go from a mask to final exposure file in even fewer steps. Write fields can be placed easily with the Automatic write field mode, which places the write fields based on the selected parameters and the design with the click of a button.

With a single run of Beamfox Proximity, it is now possible to simulate the material stack, perform proximity effect correction, fracture the design, perform polygon operations, place write fields and create advanced writing strategies, and export directly to the e-beam system file format.

Furthermore, the advanced control of write fields within Beamfox Proximity opens up for many more advanced applications:

- Flexible, user-controlled write field placement

- Floating write fields to minimize field placement errors

- Multi-pass exposure techniques

- Precise control of polygon field splitting

- Field placement optimization with virtual write fields

- Advanced writing strategies and write order control

- Alignment mark specification

With the advanced write field placement, users can easily place grids of write fields, create vector-specified write field arrays, control the overlap between write fields, enable multi-pass exposure, and specify the exact writing order, to name just a few examples.

A few of these features are highlighted below.

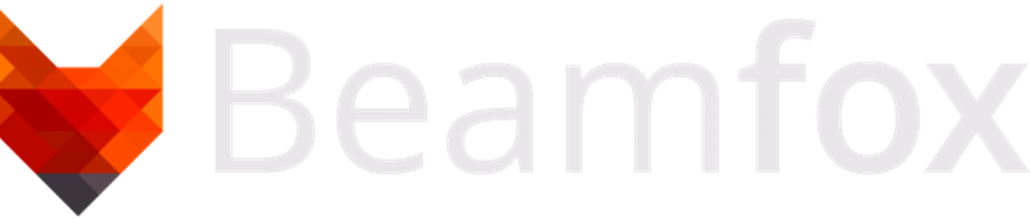

Multi-pass exposure

Geometries that lie on or near the edges of write fields are highly susceptible to stitching errors that are caused by offsets being introduced as the e-beam writer moves from one write field to the next, which can have detrimental impacts on the quality and performance of fabricated structures. This effect can be minimized using a multi-pass exposure technique, where multiple write fields are overlapped, and structures within the overlap are written multiple times at a fraction of the overall dose. This concept is illustrated in the figure below.

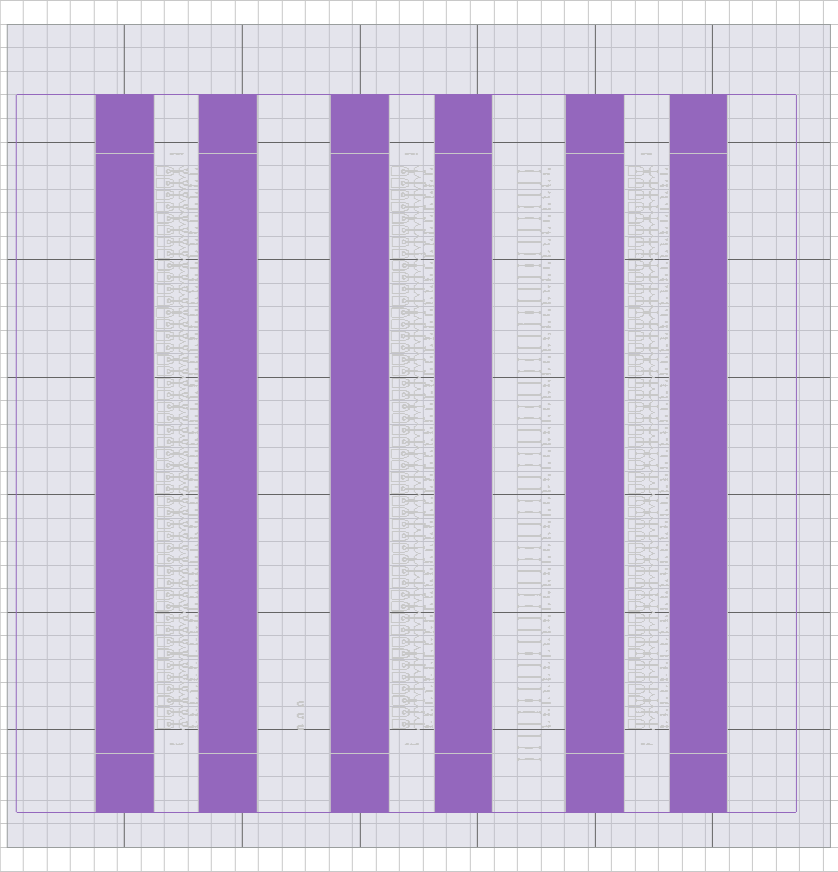

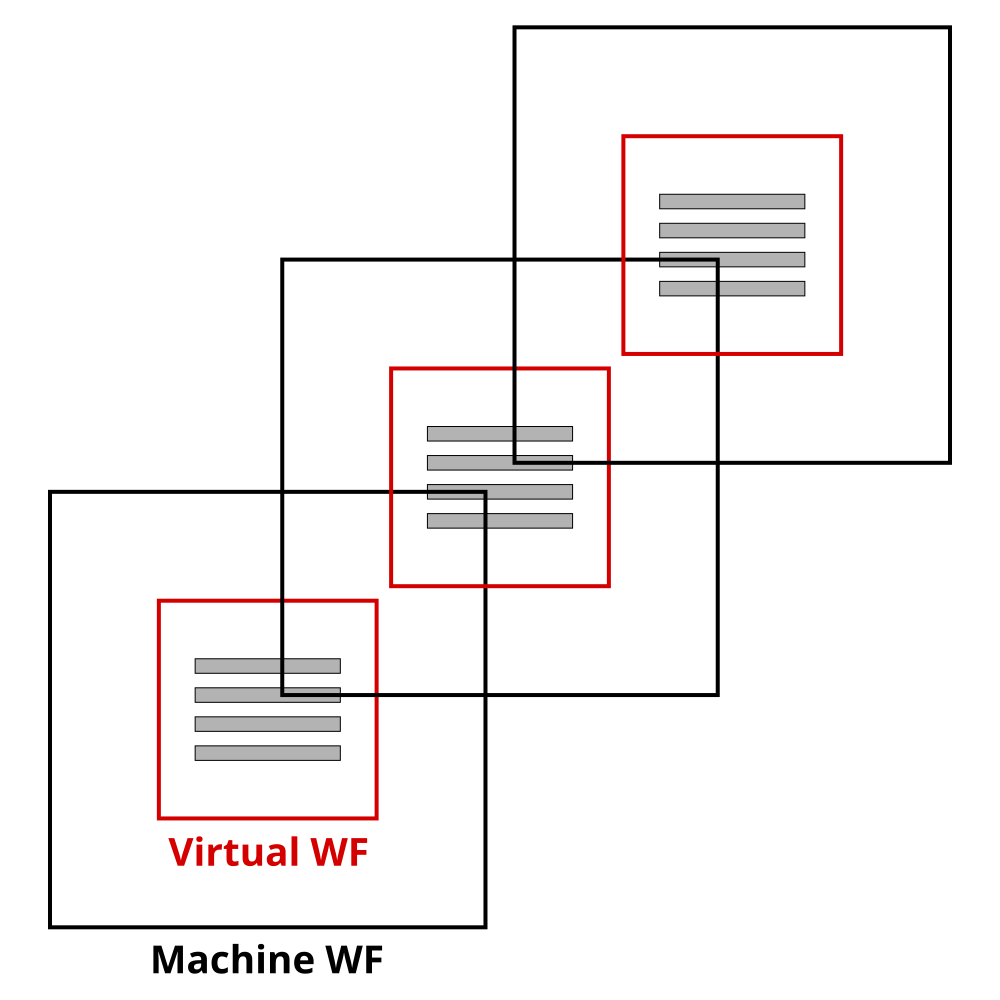

Optimized field placement with virtual and machine write fields

Modern e-beam systems can produce tightly focused electron beams, yet as the beam is deflected towards the edges of write fields, the beam will nevertheless suffer from defocusing and astigmatism. To improve the quality and fidelity of the exposure, it is therefore recommended to place geometries in the center of write fields where the beam is most tightly focused. In Beamfox Proximity, field placement can be optimized by using virtual write fields that have a different size than the machine write fields that the e-beam uses. As an example, an array of write fields of size 100 micrometers can be created for a system that uses physical write fields that are 500 micrometers in size. The geometries are then split according to the virtual write fields, and the final result is an array of overlapping 500 micrometers write fields where only the central 100 x 100 micrometer region of each write field is exposed. Virtual write fields can also be used to increase compatibility when switching between different machine write field sizes, or when switching between different e-beam systems.

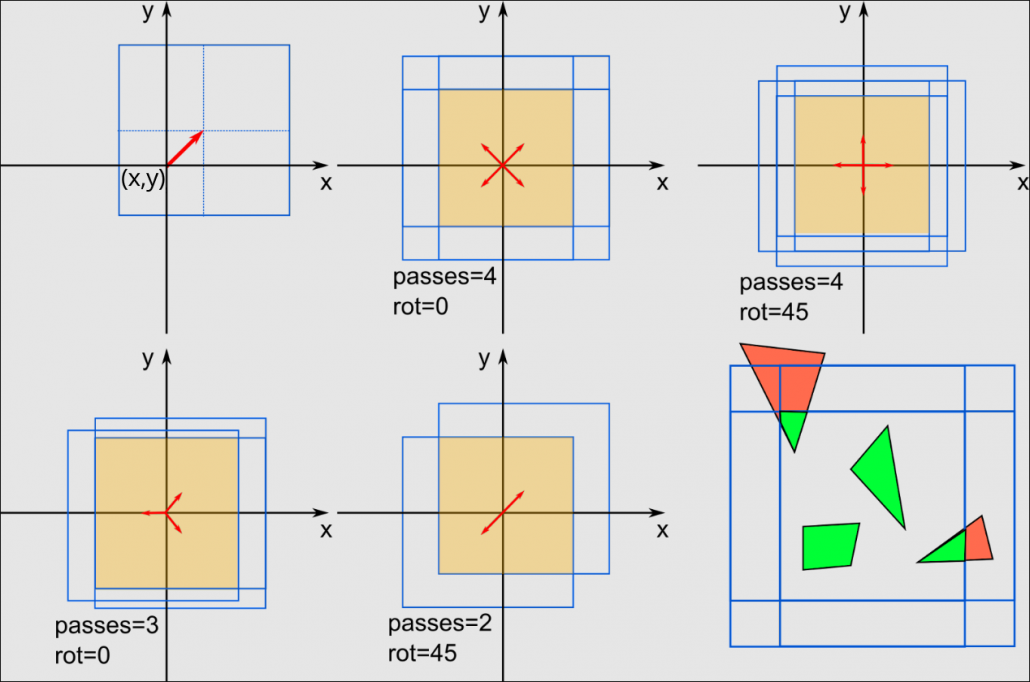

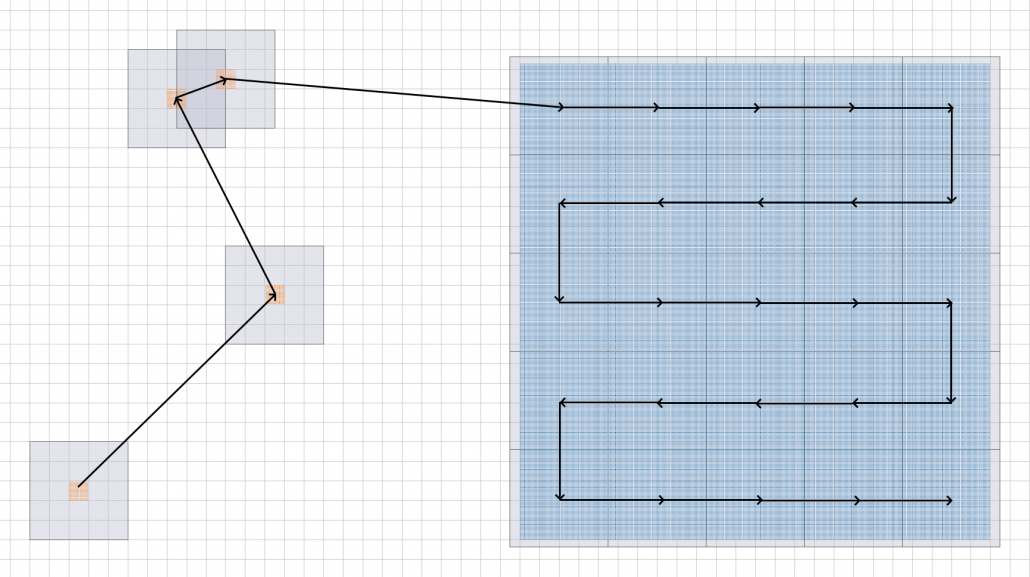

Advanced write order control

Optimizing stage travel time is a key factor in reducing the overall exposure time. Furthermore, due to errors introduced by stage movements, an optimized writing strategy can help improve exposure quality and fidelity. The advanced write field control in Beamfox Proximity allows optimizing the write field order, implementing different writing strategies such as scan and snake array writing modes, and mixing different types of write fields and writing strategies within the same exposure file.

The advanced write field placement is enabled through the use of YAML files — text files that provide the specifications of the write fields. To learn more about how to use YAML files to place and manage write fields in Beamfox Proximity, read the YAML Format Specification application note.

At the time of release, write field placement and control is supported for Elionix systems supporting the SCON and CAR file formats.

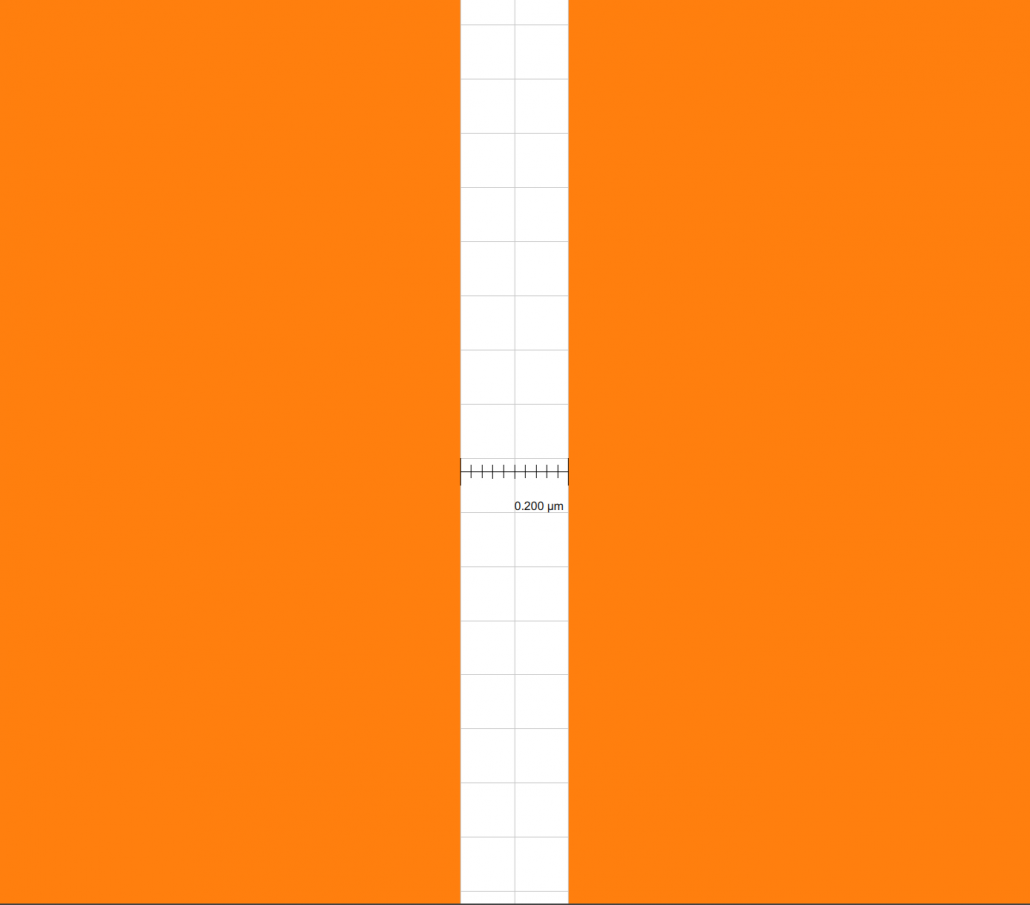

Measurement ruler

Another important inclusion in the new version is one of the most heavily-requested features by our users: a ruler!

The ruler allows for quick and easy measurements of feature sizes, distances, gaps, and more. Enable it by clicking the “Ruler” button below the mask viewer area, and right-click to place the ends of the ruler. When a polygon is highlighted by the cursor, the ruler will automatically snap to the edge of the polygon, allowing for precise measurements. Furthermore, when holding shift, the ruler will snap to move the ruler vertically or horizontally – and if the first point is at the edge of a polygon, it will even snap to create a line that is perpendicular to the polygons edge!

Further upgrades/bug fixes

- Improvements and bugfixes to mask viewer system

- Improvements to point-spread function plotting

- Improvements to polygon fracturing algorithm

- Fixed issues with layer selection

- Fixed bugs related to displayed values in material editor

- Added support for newer Elionix systems